Electricity is the “silent killer” of the industrial world. It has no smell, makes no sound until it strikes, and is invisible to the naked eye. Yet, it powers every aspect of your facility.

As an EHS Manager, you know the heavy toll this responsibility takes, often leading to sleepless nights that impact your long-term health and decision-making clarity. The fear isn’t just about failing an OSHA audit or facing massive regulatory fines—though those are real threats. The real fear is the phone call at 2:00 AM telling you that a worker has been injured, or worse, because a safety protocol was overlooked.

Navigating the labyrinth of NFPA 70E codes and OSHA regulations can feel overwhelming. But complexity is no excuse for non-compliance. You need a clear, actionable blueprint that protects your people and your business.

We are going to strip away the legal jargon and give you the actionable strategies you need to build a fortress of electrical safety in your workplace.

Table of Contents

- What is Electrical Safety in EHS?

- The “Big Three” Electrical Hazards

- Regulatory Compliance: OSHA & NFPA Decoded

- The Golden Rule: Lockout/Tagout (LOTO)

- Risk Assessment & The Hierarchy of Controls

- Training: Qualified vs. Unqualified Personnel

- Conclusion

- FAQs

What is Electrical Safety in EHS?

Workplace Electrical Safety refers to the comprehensive system of policies, procedures, and engineering controls designed to prevent electrical shock, arc flash, and electrocution. In an Environment, Health, and Safety (EHS) context, it requires integrating strict adherence to OSHA 1910 Subpart S and NFPA 70E standards with continuous employee training, rigorous equipment maintenance, and a zero-tolerance culture regarding unsafe work practices.

The “Big Three” Electrical Hazards

To defeat the enemy, you must first understand them. In the world of EHS, electrical incidents generally fall into three catastrophic categories.

1. Electric Shock

This occurs when the body becomes part of the electrical circuit. The severity depends on the path the current takes through the body, the amount of current, and the duration of exposure.

- The Risk: Ventricular fibrillation (stopping the heart) or severe internal burns.

- The Reality: Even low voltage can be lethal if the environmental conditions (wet floors, sweat) lower the body’s resistance.

2. Arc Flash

While an Arc Flash is an immediate thermal event, the aftermath often triggers broader combustion risks. For a deeper dive into mitigating these secondary hazards, reviewing protocols on fire safety awareness and protecting business assets is a critical next step for any EHS manager.

An Arc Flash is a sudden release of electrical energy through the air when a high-voltage gap exists, and there is a breakdown between conductors.

- The Risk: Temperatures can reach 35,000°F—that is four times hotter than the surface of the sun. This causes fatal burns, melts metal, and destroys lungs.

- The Reality: PPE is your last line of defense here; distance and de-energization are your first.

3. Arc Blast

This is the supersonic pressure wave produced by the expansion of gases during an Arc Flash.

- The Risk: It can throw workers across the room, collapse lungs, and rupture eardrums.

- The Reality: An Arc Blast can cause shrapnel injuries from flying equipment parts.

Regulatory Compliance: OSHA & NFPA Decoded

You cannot have a safety culture without a compliance framework. Here are the two documents that should be on your desk at all times.

OSHA 1910 Subpart S (The Law)

This is the “Shall”. OSHA regulations are federal law. Subpart S covers the design of electrical systems and safety-related work practices.

- Key Focus: Employers must provide a workplace free from recognized hazards.

- Most Cited Violation: Improper use of extension cords and lack of ground-fault circuit interrupters (GFCIs).

NFPA 70E (The “How-To”)

This is the Standard for Electrical Safety in the Workplace. While OSHA tells you what to do (be safe), NFPA 70E tells you how to do it.

- Key Focus: Establishing an “Electrically Safe Work Condition.”

- Update Cycle: Updated every 3 years (Current: 2024 Edition). If you are using the 2018 version, you are non-compliant.

Pro Tip: OSHA frequently uses NFPA 70E as evidence of “recognized industry hazards” during citations. Ignoring NFPA 70E is essentially ignoring OSHA.

The Golden Rule: Lockout/Tagout (LOTO)

If there is one takeaway from this entire guide, let it be this: De-energize before you work.

Lockout/Tagout (LOTO) is the physical restraint of all hazardous energy sources that supply power to a piece of equipment. It is not just a padlock; it is a life-saving procedure.

The 6 Essential Steps of LOTO:

- Preparation: Notify affected employees and identify energy sources.

- Shutdown: Turn off the machine using standard operating procedures.

- Isolation: Disconnect the energy source (pull the switch/breaker).

- Lockout/Tagout: Apply your assigned lock and tag. Never use someone else’s lock.

- Stored Energy Check: Release or restrain residual energy (capacitors, springs, gravity).

- Verification (The Most Important Step): Try to start the machine. Test with a voltage meter to ensure “Dead.”

Common EHS Mistake: assuming a machine is off just because the control panel says so. Always “Test Before Touch.”

Risk Assessment & The Hierarchy of Controls

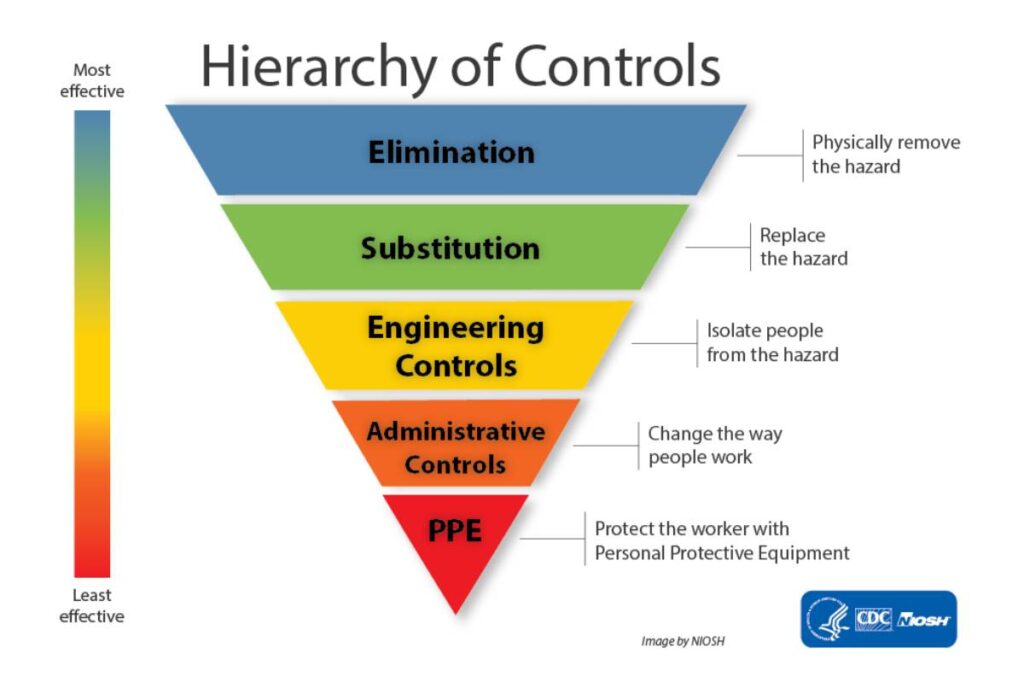

As an EHS leader, your job is to mitigate risk. You should apply the NIOSH Hierarchy of Controls to electrical safety.

- Elimination (Most Effective): Physically remove the hazard.

- Example: De-energizing the circuit completely.

- Substitution: Replace the hazard.

- Example: Using 24V control voltage instead of 110V where possible.

- Engineering Controls: Isolate people from the hazard.

- Example: Installing GFCIs, touch-safe covers, and remote racking devices.

- Administrative Controls: Change the way people work.

- Example: LOTO procedures, permit-to-work systems, and safety audits.

- PPE (Least Effective): Protect the worker with gear.

- Example: Rubber insulating gloves, Arc Flash suits, and face shields.

Note: PPE is vital, but it is the last resort. If your safety plan relies solely on PPE, your plan is flawed.

Training: Qualified vs. Unqualified Personnel

Who is allowed to open that panel? OSHA makes a strict distinction here.

Qualified Person

One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and has received safety training to identify the hazards involved.

- Can: Test for voltage, perform LOTO, work within the Limited Approach Boundary.

- Must: Receive training specific to the equipment they work on.

Unqualified Person

Everyone else. They may be trained on how to avoid electrical hazards, but they cannot work on or near exposed energized parts.

- Can: Operate standard office equipment or machines with all guards in place.

- Must: Stay outside the Limited Approach Boundary.

EHS Action Item: Review your training logs. Do you have documentation proving your “Qualified” staff have demonstrated proficiency? A written test isn’t enough; hands-on verification is required.

Conclusion

Electrical safety isn’t about ticking boxes on a clipboard. It is about ensuring that every father, mother, son, and daughter who walks into your facility walks out of it in the same condition at the end of their shift.

By implementing strict LOTO procedures, adhering to NFPA 70E, and prioritizing Engineering Controls over PPE, you move from a reactive “accident-prone” environment to a proactive Safety Culture.

Ask yourself this today: If an OSHA inspector walked through your electrical maintenance room right now, would you feel confident, or would you feel panic?

If the answer is panic, it’s time to audit your EHS protocols. Whether you need a comprehensive risk assessment or a system upgrade, partnering with experts—such as Reds Power Solutions in Sydney—can be the decisive factor in securing your site and protecting your workforce.

FAQs

What is the difference between OSHA and NFPA 70E?

OSHA is the federal law requiring a safe workplace, while NFPA 70E is the consensus industry standard that defines how to comply with OSHA’s electrical requirements. OSHA enforces the law; NFPA 70E provides the playbook.

How often is electrical safety training required?

According to NFPA 70E, retraining is required at least every three years. However, immediate retraining is necessary if inspections reveal unsafe practices, if new equipment is introduced, or if job duties change.

What is an Arc Flash Boundary?

The Arc Flash Boundary is the distance from an exposed energized part where a worker would receive the onset of a second-degree burn (1.2 calories/cm²) if an arc flash occurred. Within this boundary, specific PPE is mandatory.

Can I work on live electrical circuits?

Generally, NO. OSHA allows work on energized parts only if de-energizing introduces increased hazards (e.g., life-support systems) or is infeasible due to equipment design (e.g., diagnostics/testing). Inconvenience is never a valid reason for live work.